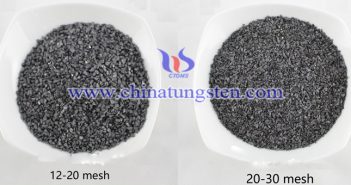

Coarse tungsten powder is a coarse-grained tungsten powder compared with other grain size. It is a raw material of crude tungsten carbide, with a purity greater than 99.9%. Application The coarse tungsten powder with uniform grain size is the raw material for producing coarse tungsten carbide. The more coarse the tungsten carbide particles are, the more coarse the coarse tungsten powder should be. Tungsten carbide particle size first determine the size of coarse tungsten powder, the temperature and other conditions…