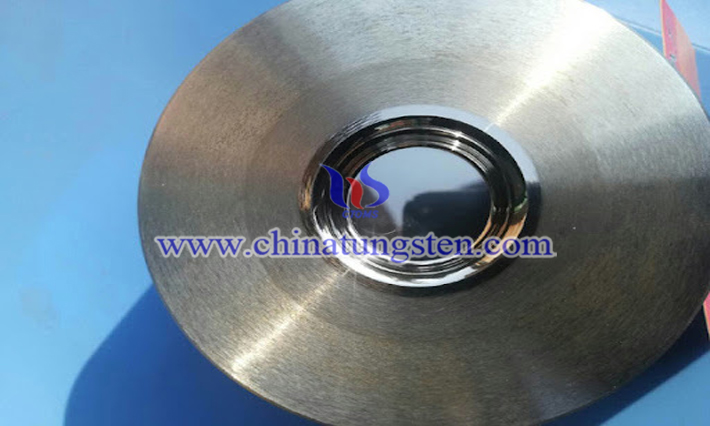

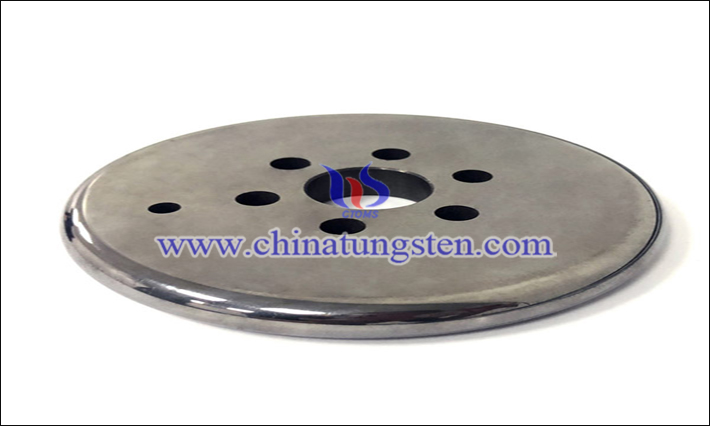

Tungsten Alloy Extrusion Die is a technology for forming parts by extrusion die in the process of high-strength extrusion.

This technology can not only prevent the extrusion rod from delamination or cracking, but also reduce the cross-section of the molded part and increase its length. Tungsten Alloy Extrusion Dies have some excellent properties such as high thermal stability, high wear resistance, easy machinability, non-friability, good machinability and excellent crack resistance, and are widely used in extrusion dies.

The extrusion die made of tungsten alloy has the characteristics of high hardness, corrosion resistance, impact resistance and heat resistance, which ensures that it will not deform under high temperature and high pressure, and still maintains its hardness, while other metal materials have been deformed or melted. Compared with traditional materials, it has a longer service life and can ensure the minimum shrinkage of die-cast components in the extrusion process. Therefore, the Tungsten Alloy Extrusion Die has high quality and high performance.

There are three main extrusion methods of Tungsten Alloy Extrusion Die.

1.Cold Extrusion generally refers to the processing method of placing the blank in a cold extrusion die cavity and applying pressure to the blank through a punch fixed on a press at room temperature, so that the blank is plastically deformed to produce parts.

Advantages: The product has high precision and can be cut with little or no cutting; High strength performance; High labor productivity, can process complex mechanical parts, etc.

2.Warm Extrusion, generally refers to the blank below the recrystallization temperature of metal and at the recovery temperature (when the metal after cold deformation is heated to a certain temperature, the opposite transformation will occur.) the extrusion performed above.

Advantages: it can reduce the metal deformation resistance and improve the processing plasticity; Maintains the advantage of improving the strength performance of finished products by cold extrusion;

3.Hot Extrusion generally refers to various extrusion forming of metals above the recrystallization temperature of metals with the help of good plasticity of materials.

Advantages: Good forming plasticity; Increase metal strength;